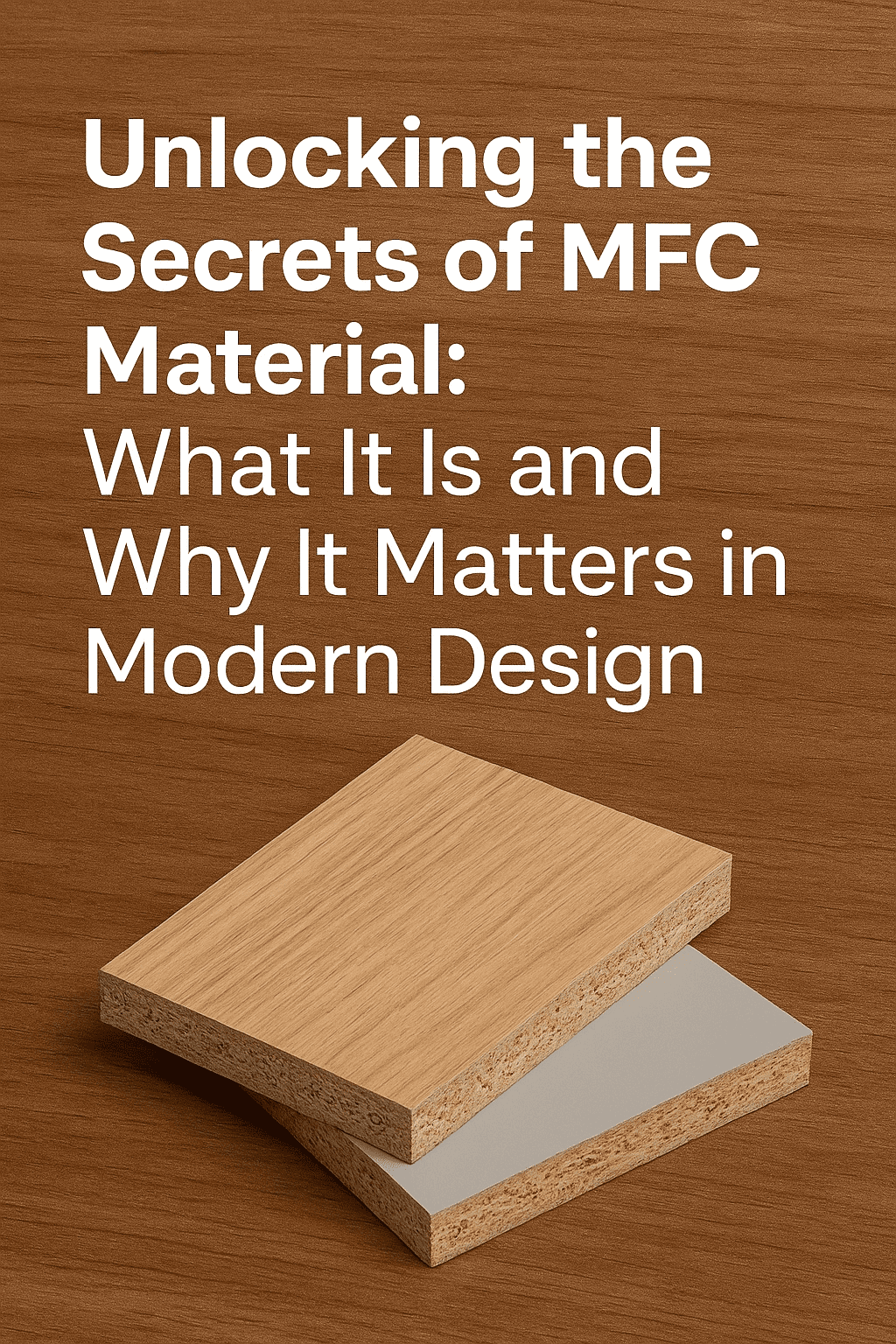

Unlocking the Secrets of MFC Material: What It Is and Why It Matters in Modern Design

In the ever-evolving world of design, staying ahead means understanding the materials that drive innovation. Enter MFC material short for Melamine Faced Chipboard a game-changer in the realm of modern aesthetics and functionality. This versatile material seamlessly combines style and practicality, making it a preferred choice for designers and manufacturers alike. But what exactly is MFC, and why is it becoming increasingly essential in contemporary design projects?

From its striking finishes to its durable structure, MFC material offers a wealth of possibilities for everything from furniture to cabinetry. In this article, we will dive into the secrets of MFC, uncovering its benefits, applications, and the reasons why it stands out in today’s material landscape. Get ready to discover how MFC can elevate your design projects and transform spaces with a touch of modern elegance. Join us as we unlock the potential of MFC material and reveal why it truly matters in the design industry!

Unlocking the Secrets of MFC Material: What It Is and Why It Matters in Modern Design

In the ever-evolving world of design, staying ahead means understanding the materials that drive innovation. Enter MFC material short for Melamine Faced Chipboard a game-changer in the realm of modern aesthetics and functionality. This versatile material seamlessly combines style and practicality, making it a preferred choice for designers and manufacturers alike. But what exactly is MFC, and why is it becoming increasingly essential in contemporary design projects? From its striking finishes to its durable structure, MFC material offers a wealth of possibilities for everything from furniture to cabinetry. In this article, we will dive into the secrets of MFC, uncovering its benefits, applications, and the reasons why it stands out in today’s material landscape. Get ready to discover how MFC can elevate your design projects and transform spaces with a touch of modern elegance. Join us as we unlock the potential of MFC material and reveal why it truly matters in the design industry!

The Composition and Properties of MFC

Melamine Faced Chipboard (MFC) is an engineered wood product that boasts a unique composition and a plethora of advantageous properties. At its core, MFC is composed of wood chips bound together with a synthetic resin. This core is then faced with a melamine-impregnated paper, which undergoes a pressing process to fuse the layers together. The result is a robust and aesthetically appealing material that can mimic the look of natural wood or other designs through various finishes and textures.

One of the standout properties of MFC is its durability. The melamine surface layer provides a hard, scratch-resistant finish that can withstand daily wear and tear. This makes MFC an excellent choice for high-traffic areas and applications where surfaces are prone to frequent use. Additionally, MFC is resistant to moisture and stains, which further enhances its suitability for environments such as kitchens and bathrooms. These properties ensure that MFC maintains its appearance and integrity over time, even under demanding conditions.

Another noteworthy characteristic of MFC is its versatility in design. The melamine facing can be customized to achieve a wide range of colors, patterns, and textures, allowing designers to create aesthetically pleasing and cohesive spaces. Whether it’s a sleek, modern look or a more traditional, wood-like appearance, MFC can be tailored to meet diverse design preferences. This adaptability makes MFC a go-to material for achieving both functional and visually appealing design solutions in various settings.

Advantages of Using MFC in Design

The advantages of using MFC in design are numerous and multifaceted, making it a valuable material for both residential and commercial projects. One of the primary benefits is its cost-effectiveness. Compared to solid wood and other premium materials, MFC offers a more affordable alternative without compromising on quality or aesthetics. This cost efficiency allows designers and homeowners to achieve high-end looks and durable solutions within budget constraints.

In addition to its affordability, MFC is also highly versatile in its applications. Its ability to be customized with a wide range of finishes means it can seamlessly integrate into different design styles, from contemporary to classic. This versatility extends to its use in various types of furniture, cabinetry, wall panels, and more. The consistent quality and uniformity of MFC make it a reliable choice for mass production, ensuring that design elements maintain their intended appearance across multiple pieces.

Another significant advantage of MFC is its ease of maintenance. The melamine surface is non-porous, making it resistant to stains and easy to clean. This low-maintenance aspect is particularly appealing in busy environments where cleanliness and upkeep are important. Additionally, MFC does not require the same level of care and preservation as natural wood, such as regular polishing or treating, which further simplifies its upkeep. This practicality, combined with its aesthetic appeal, makes MFC an attractive option for a wide range of design projects.

Common Applications of MFC in Modern Design

MFC’s versatility and durability make it an ideal material for numerous applications in modern design. One of the most common uses of MFC is in the construction of furniture. From office desks and shelving units to bedroom wardrobes and dining tables, MFC’s sturdy composition and attractive finishes make it suitable for a variety of furniture pieces. Its ability to mimic natural wood grains and other textures allows designers to create stylish and functional furniture that enhances the overall aesthetic of a space.

Another prominent application of MFC is in kitchen and bathroom cabinetry. The moisture-resistant properties of MFC make it particularly well-suited for these environments, where surfaces are frequently exposed to water and humidity. MFC cabinets offer a blend of functionality and style, providing ample storage solutions while maintaining a sleek and modern appearance. Additionally, the ease of cleaning and maintenance associated with MFC makes it a practical choice for areas that require regular upkeep.

MFC is also widely used in interior wall paneling and partitions. Its ability to be customized with various finishes means it can be used to create feature walls and decorative panels that add visual interest and depth to a space. In commercial settings, MFC is often employed in the construction of office furniture, retail displays, and exhibition stands, where its durability and aesthetic flexibility are highly valued. The material’s consistent quality and ease of fabrication make it a preferred choice for large-scale projects that require uniformity and precision.

MFC vs. Other Materials: A Comparative Analysis

When comparing MFC to other materials, several key factors come into play, including cost, durability, aesthetics, and environmental impact. One of the main competitors to MFC is Medium Density Fiberboard (MDF). Both materials are engineered wood products, but they have distinct differences. MFC typically outshines MDF in terms of surface durability due to its melamine finish, which provides better resistance to scratches and moisture. While MDF can be painted or veneered, it does not offer the same level of scratch and stain resistance as MFC.

Another material often compared to MFC is plywood. Plywood consists of multiple layers of wood veneers bonded together, offering high strength and stability. However, plywood is generally more expensive than MFC and may not provide the same range of customizable finishes. While plywood is favored for structural applications where strength is paramount, MFC is preferred for its aesthetic versatility and cost-effectiveness in non-structural applications.

Solid wood is another alternative to MFC, known for its natural beauty and strength. However, solid wood comes at a higher cost and requires more maintenance to preserve its appearance. It is also more susceptible to warping and damage from moisture. MFC, with its engineered core and durable melamine surface, offers a more stable and low-maintenance option that can mimic the look of natural wood. This makes MFC an attractive choice for those seeking the visual appeal of wood without the associated drawbacks.

Sustainability and Environmental Impact of MFC

As sustainability becomes an increasingly important consideration in design and manufacturing, the environmental impact of materials is scrutinized more closely. MFC has certain sustainable attributes that contribute to its appeal. The core of MFC is made from wood chips, which are often sourced from by-products of other wood processing activities. This efficient use of wood resources helps reduce waste and promotes the utilization of renewable materials.

Moreover, MFC production typically involves less energy consumption compared to the manufacturing of solid wood furniture. The melamine resin used in MFC can also be produced with lower emissions of volatile organic compounds (VOCs), contributing to better indoor air quality. Additionally, many MFC products are certified by environmental standards such as the Forest Stewardship Council (FSC), ensuring that the wood used comes from responsibly managed forests.

Despite these advantages, it is important to consider the full lifecycle of MFC products. The melamine resin, while providing durability, is a synthetic material that may not be as environmentally benign as natural alternatives. End-of-life disposal can also pose challenges, as MFC is not as easily recyclable as some other materials. However, ongoing advancements in recycling technologies and sustainable production methods are helping to mitigate these concerns, making MFC a more environmentally friendly option in modern design.

Trends in MFC Usage within the Design Industry

The design industry is constantly evolving, and MFC is at the forefront of several emerging trends. One notable trend is the increasing demand for customizable and unique finishes. Designers are leveraging the versatility of MFC to create bespoke pieces that cater to specific aesthetic preferences and functional requirements. This trend is particularly evident in the residential sector, where homeowners seek personalized and distinctive interior solutions.

Another trend is the integration of MFC with other materials to achieve a multi-dimensional look. Combining MFC with metal, glass, and fabric can create visually striking contrasts and enhance the overall design narrative. This hybrid approach allows designers to play with textures and finishes, adding depth and character to spaces. The ability of MFC to seamlessly blend with other materials makes it an ideal choice for achieving such innovative and dynamic designs.

Sustainability is also shaping the future of MFC usage. As consumers become more environmentally conscious, there is a growing demand for eco-friendly materials. MFC manufacturers are responding by adopting sustainable practices and producing products with lower environmental footprints. This includes using recycled wood content, reducing VOC emissions, and improving the recyclability of MFC products. The trend towards sustainable design is likely to drive further innovation in MFC technology and expand its applications.

Tips for Selecting the Right MFC for Your Project

Choosing the right MFC for your project involves several key considerations to ensure that the material meets your design and functional requirements. Firstly, it is important to assess the intended application and environment. For high-moisture areas such as kitchens and bathrooms, opt for moisture-resistant MFC variants that provide enhanced durability. Similarly, for high-traffic areas, select MFC with a robust melamine surface that can withstand frequent use and potential damage.

The aesthetic aspects of MFC are also crucial in the selection process. Consider the color, pattern, and texture that best align with your design vision. MFC is available in a wide range of finishes, from wood grains to solid colors and intricate patterns. Evaluate samples to ensure that the chosen finish complements the overall design scheme and achieves the desired visual impact. It is also beneficial to consider the edge banding options, as this can affect the final appearance and durability of the MFC panels.

Quality and certification are other important factors to consider. Choose MFC products that are certified by reputable standards such as the FSC or PEFC, which indicate responsible sourcing and sustainable practices. Additionally, inquire about the manufacturing process and the quality control measures in place to ensure that the MFC panels meet industry standards. Working with reputable suppliers and manufacturers can provide assurance of the material’s quality and consistency.

Future Innovations in MFC Technology

The future of MFC technology holds exciting potential for further advancements and innovations. One area of development is the enhancement of surface finishes. Researchers and manufacturers are exploring new coating technologies and treatments that can further improve the durability, scratch resistance, and aesthetic qualities of MFC. These advancements aim to extend the lifespan of MFC products and expand their suitability for even more demanding applications.

Another promising area of innovation is the integration of smart features into MFC. This includes the incorporation of embedded sensors, lighting, and connectivity options that can transform MFC panels into interactive and multifunctional surfaces. Such smart MFC products can enhance the functionality of furniture and interior elements, offering features such as touch controls, illumination, and data collection. These innovations have the potential to revolutionize the way we interact with our built environments.

Sustainability will continue to drive future innovations in MFC technology. Efforts are being made to develop more eco-friendly resins and adhesives that reduce the environmental impact of MFC production. Additionally, advancements in recycling and upcycling processes are being pursued to improve the end-of-life management of MFC products. These initiatives aim to create a more sustainable lifecycle for MFC, aligning with the growing demand for environmentally responsible design solutions.

Conclusion: Embracing MFC for Contemporary Design Solutions

In conclusion, MFC material stands out as a versatile and innovative solution in the world of contemporary design. Its unique composition and properties offer a harmonious blend of durability, aesthetics, and practicality that cater to a wide range of applications. From furniture and cabinetry to wall paneling and commercial fixtures, MFC proves to be a reliable and cost-effective choice that meets diverse design needs.

The advantages of using MFC extend beyond its immediate functional and visual benefits. Its sustainability attributes and the ongoing advancements in eco-friendly production methods align with the increasing emphasis on responsible design practices. As the design industry evolves, MFC continues to adapt and innovate, offering new possibilities and solutions that enhance the built environment.

Whether you are a designer, manufacturer, or homeowner, understanding the potential of MFC can elevate your projects and contribute to the creation of beautiful, functional, and sustainable spaces. Embrace MFC material in your design endeavors and unlock the secrets of its transformative power in modern design.